LiFePO4 Battery Vs Lithium Ion Battery : A Comparative Analysis

Introduction:

As the demand for efficient and reliable energy storage solutions continues to grow, two prominent contenders have emerged: LiFePO4 (Lithium Iron Phosphate) batteries and Lithium Ion batteries. In this article, we will delve into the key differences between these two battery technologies and explore their respective advantages in various applications.

What is LiFePO4 Battery?

LiFePO4 Battery also means LFP battery, which is a highly stable but slightly less energy dense battery composition. The iron and phosphate used to make the cathode are abundant and cheap than some of the materials used in NMC batteries – mainly cobalt. In addition, the materials in LiFePO4 batteries are far less toxic than those in NMC, making them easier to recycle at the end of their life.

Currently, more and more companies have been manufacturing LiFePO4 batteries as opposed to NMC for home energy storage. Mostly because LiFePO4 batteries are safer and more stable. In ELB, there are two model are popular in home energy storage system:

LiFePO4 Summary Table

|

Voltages

|

3.20, 3.30V nominal; typical operating range 2.5–3.65V/cell

|

|

Specific energy (capacity)

|

90–120Wh/kg

|

|

Charge (C-rate)

|

1C typical, charges to 3.65V; 3h charge time typical

|

|

Discharge (C-rate)

|

1C, 25C on some cells; 40A pulse (2s); 2.50V cut-off (lower that 2V causes damage)

|

|

Cycle life

|

2000 and higher (related to depth of discharge, temperature)

|

|

Thermal runaway

|

270°C (518°F) Very safe battery even if fully charged

|

|

Cost

|

~$XXX per kWh

|

|

Applications

|

ESS, EVs, etc

|

LiFePO4 batteries offer several advantages that make them highly sought-after in the energy storage industry. Some key features include:

- Safety: LiFePO4 batteries are inherently stable and exhibit excellent thermal stability, making them resistant to thermal runaway, explosion, or fire risks. This safety aspect has positioned LiFePO4 batteries as a preferred choice in applications where safety is paramount.

- Longevity: LiFePO4 batteries boast an impressive lifespan, with a typical cycle life of over 2,000 cycles. This extended lifespan ensures a longer service life, resulting in reduced replacement and maintenance costs.

- High Discharge Rates: LiFePO4 batteries can deliver high discharge currents, making them ideal for applications that require a burst of power or high current draw. They are commonly used in applications such as electric vehicles (EVs) and renewable energy systems.

What is Lithium ion battery?

The most widely cited Lithium ion battery is the ternary battery, we also call it as NMC battery also means NiCoMn ternary battery. Which is a very high specific energy or power battery. This limitation of “energy” or “power” makes them more commonly used in power tools or electric cars.

NMC lithium ion batteries typically have a lower upfront cost but may need to be replaced over the lifetime of the vessel depending on the operational profile.

NMC Lithium Ion Battery Summary Table

|

Voltages

|

3.60V, 3.70V nominal; typical operating range 3.0–4.2V/cell, or higher

|

|

Specific energy (capacity)

|

150–220Wh/kg

|

|

Charge (C-rate)

|

0.7–1C, charges to 4.20V, some go to 4.30V; 3h charge typical. Charge current above 1C shortens battery life.

|

|

Discharge (C-rate)

|

1C; 2C possible on some cells; 2.50V cut-off

|

|

Cycle life

|

1000–2000 (related to depth of discharge, temperature)

|

|

Thermal runaway

|

210°C (410°F) typical. High charge promotes thermal runaway

|

|

Cost

|

~$XXX per kWh

|

|

Applications

|

E-bikes, medical devices, EVs, industrial

|

Lithium Ion batteries are well-known for their energy density and versatility. Here are some notable advantages of Lithium Ion batteries:

- Energy Density: Lithium Ion batteries offer a higher energy density compared to LiFePO4 batteries, allowing for more energy storage in a smaller and lighter package. This advantage makes Lithium Ion batteries suitable for portable devices, such as smartphones and laptops.

- Voltage Range: Lithium Ion batteries have a wider voltage range, enabling them to deliver a more consistent voltage output throughout most of their discharge cycle. This voltage stability is crucial in applications where a constant power supply is required, such as electric grids and uninterruptible power supply (UPS) systems.

Performance: Lithium Ion batteries exhibit excellent efficiency and have a lower self-discharge rate than LiFePO4 batteries. They also provide a higher charging efficiency, allowing for faster recharging times.

Which is the best? LiFePO4 battery vs Lithium Ion Battery?

Performance

Overall, the overall performance of Lithium ion cell and LiFePO4 cells is almost the same. You can find these two types in a variety of sizes, from as little as 0.5 kWh to over 100 kWh. Most homeowners only need about 10 kWh of storage, and you can definitely find it from both types.

That being said, there are some subtle differences between the two. Compared to Lithium ion battery, LiFePO4 battery are slightly more efficient and operate better at lower states of charge, but NMCs can tolerate cooler temperatures better. However, if your battery is installed inside, or if you’re in an area that doesn’t experience significant temperature extremes, you probably don’t need to worry about this.

Lithium ion batteries also have higher energy density, which means they will be physically smaller than LiFePO4 batteries of the same capacity. This is usually not a concern for homeowners, but if you have limited space then you may want to consider Lithium ion batteries.

Lifespan

Generally speaking, the cycle life of LiFePO4 battery is more than 6000 times, while the life of ternary lithium ion battery is generally 800-1000 times.

Safety

One of the biggest benefits of choosing an LiFePO4 battery is its safety and lifespan. The combination of lithium iron phosphate is more stable than nickel manganese cobalt at higher temperatures.

Additionally, LiFePO4 batteries can better handle greater power consumption. Therefore, LiFePO4 cells are less likely to experience thermal runaway. In short, LiFePO4 batteries are less likely to catch fire than lithium ion batteries.

This is not to say that if you install an lithium ion battery, it will spontaneously ignite. However, if the lithium ion battery is overstressed or mishandled, there is a higher chance of problems. That’s why it’s important to use a licensed, trusted battery installer to minimize the chance of problems.

Upfront Cost

lithium ion batteries tend to be a little more expensive than LiFePO4 batteries.

Also, the LiFePO4 battery is slightly larger, and the cabinet housing the LiFePO4 battery may also require more material.

Value

We’re just saying that lithium ion batteries have a lower upfront cost. However, LiFePO4 batteries can give you great value for money.

According to the price of each cycle life, the price per cycle of LFP Battery is only 1/3 of the price per cycle of lithium ion battery basically.

Charge-Discharge Curve

Let’s compare the charge-discharge curves of LiFepo4 Battery Vs Lithium Ion batteries:

The state of charge (SOC) of an lithium ion battery varies significantly by its voltage level.

On the other hand, the SOC level of lithium iron phosphate batteries, due to its flat charge-discharge curve, is not easy to distinguish by voltage level.

Therefore, accurate SOC diagnosis of lithium ion batteries is possible, while SOC accuracy of LiFePO4 batteries is very challenging.

How To Choice The Right One For You?

Commercially, the initial capital expenditure for LiFePO4 cells is generally cheaper than for NMC lithium cells. LiFePO4 batteries are about 20-30% cheaper per kWh, but system integration costs tend to be only about 5-15% cheaper at the beginning of the overall system life cycle.

Operationally, we like the LiFePO4 batteries more relaxed operating conditions – a wider temperature range than NMC, and does not require refrigerated containers for shipping. In addition, LiFePO4 battery products generally support up to 1C operation, while Lithium ion battery must use power batteries, 2H or 4H different batteries use batteries, support 1C rate (1 hour) applications, and the cost is high.

We believe it is important that customer and investor awareness of Lithium ion batteries and companies remains high. But leading lithium iron phosphate batteries and companies have been catching up. Once a product is approved, customers can often easily adopt the same company’s new platform.

Where you can find the best LiFePO4 battery and Lithium ion battery?

CONSNANT manufactures both LiFePO4 Battery and Lithium ion battery which adopts latest technology. So when trying to decide which battery to purchase consider a few things.

1. What application are you using the battery for?

2. What is the discharge/discharge current of the batteries?

3. The size limitation of the battery space?

4. Energy density will be high or low?

When considering battery technology for a particular application, it is essential to assess the specific requirements and prioritize factors such as safety, energy density, lifespan, and discharge rates. By understanding these differences, consumers and businesses can make informed decisions to meet their energy storage effectively.

Once you have the answers to these questions CONSNANT will help you to determine the best battery for you. Let us know your opinion about the above topic. Any question, welcome to contact with us!

Power Supply Issue: Check if the main power outlet is on and ensure the power supply is working.

Power Supply Issue: Check if the main power outlet is on and ensure the power supply is working. Charging Contact Issue: Make sure the stair lift is parked at the charging point. Check if the charging strip is clean and undamaged.

Charging Contact Issue: Make sure the stair lift is parked at the charging point. Check if the charging strip is clean and undamaged.

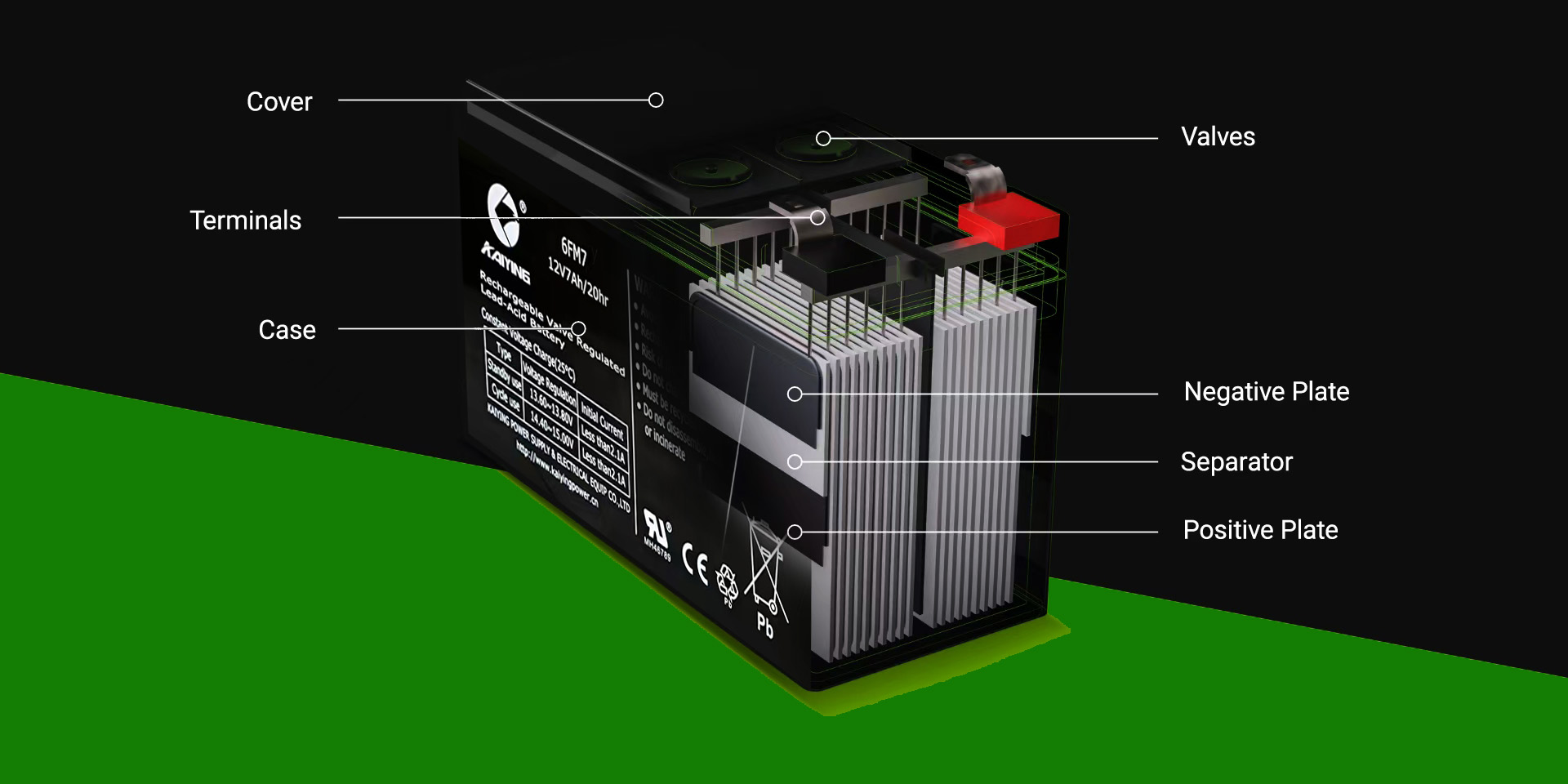

Medical Equipment: Used in 65% of fixed UPS systems (e.g., ventilator backups) due to deep-discharge resilience (92% capacity retention at 80% DOD) and minimal maintenance.

Medical Equipment: Used in 65% of fixed UPS systems (e.g., ventilator backups) due to deep-discharge resilience (92% capacity retention at 80% DOD) and minimal maintenance.  Security Systems: Dominate fire alarms and access control units, withstanding high temperatures (30% longer lifespan at 45°C) and offering rapid global delivery (72-hour turnaround).

Security Systems: Dominate fire alarms and access control units, withstanding high temperatures (30% longer lifespan at 45°C) and offering rapid global delivery (72-hour turnaround).  Kids’ Ride-On Cars: Hold 90% market share with low cost (<$7 per 12V7AH unit) and plug-and-play compatibility.

Kids’ Ride-On Cars: Hold 90% market share with low cost (<$7 per 12V7AH unit) and plug-and-play compatibility.  Data Centers: AI-driven power demands favor lithium-ion BBUs (Backup Battery Units). NVIDIA’s GB300 servers now use lithium cells, with global BBU demand hitting 220 million units by 2025—60% driven by cloud giants like Microsoft and Google.

Data Centers: AI-driven power demands favor lithium-ion BBUs (Backup Battery Units). NVIDIA’s GB300 servers now use lithium cells, with global BBU demand hitting 220 million units by 2025—60% driven by cloud giants like Microsoft and Google.  Portable Medical Devices: Handheld ultrasound tools adopt 18650 lithium cells, cutting weight by 30% while meeting UL 1642 safety standards.

Portable Medical Devices: Handheld ultrasound tools adopt 18650 lithium cells, cutting weight by 30% while meeting UL 1642 safety standards.  Smart Security Cameras: Lithium batteries power wireless cameras, offering 2,000+ cycles (vs. 350 cycles for lead-acid) and cold-weather performance (-30°C operation).

Smart Security Cameras: Lithium batteries power wireless cameras, offering 2,000+ cycles (vs. 350 cycles for lead-acid) and cold-weather performance (-30°C operation).  Southeast Asia: Frequent blackouts (>120 hours/year) keep lead-acid dominant (78% share), but India and Indonesia impose 15% tariffs to protect local producers.

Southeast Asia: Frequent blackouts (>120 hours/year) keep lead-acid dominant (78% share), but India and Indonesia impose 15% tariffs to protect local producers.  Europe & North America: Lithium penetration exceeds 60%, driven by EU’s CE certification (phasing out 30% of low-quality products) and Germany’s 5,000-cycle lifespan mandate for energy storage.

Europe & North America: Lithium penetration exceeds 60%, driven by EU’s CE certification (phasing out 30% of low-quality products) and Germany’s 5,000-cycle lifespan mandate for energy storage.  China: Lead-acid demand grows 25% annually in western data centers (“East Data West Computing” project), while new energy policies push lithium adoption.

China: Lead-acid demand grows 25% annually in western data centers (“East Data West Computing” project), while new energy policies push lithium adoption.  Lead-Acid Costs: High lead prices (~$2,450/ton) favor companies with in-house smelting (e.g., Yuguang Gold Lead), while smaller recyclers struggle.

Lead-Acid Costs: High lead prices (~$2,450/ton) favor companies with in-house smelting (e.g., Yuguang Gold Lead), while smaller recyclers struggle.  Lithium Tech Race: Samsung SDI’s “all-pole ear” cells boost power density by 15%, and Chinese firms like Tianneng Energy supply Microsoft/NVIDIA in non-U.S. markets.

Lithium Tech Race: Samsung SDI’s “all-pole ear” cells boost power density by 15%, and Chinese firms like Tianneng Energy supply Microsoft/NVIDIA in non-U.S. markets.  Regulatory Hurdles: EU’s RoHS 2.0 rules (lead content ≤0.1%) force lead-acid makers to upgrade recycling tech (e.g., silver paste recovery).

Regulatory Hurdles: EU’s RoHS 2.0 rules (lead content ≤0.1%) force lead-acid makers to upgrade recycling tech (e.g., silver paste recovery).

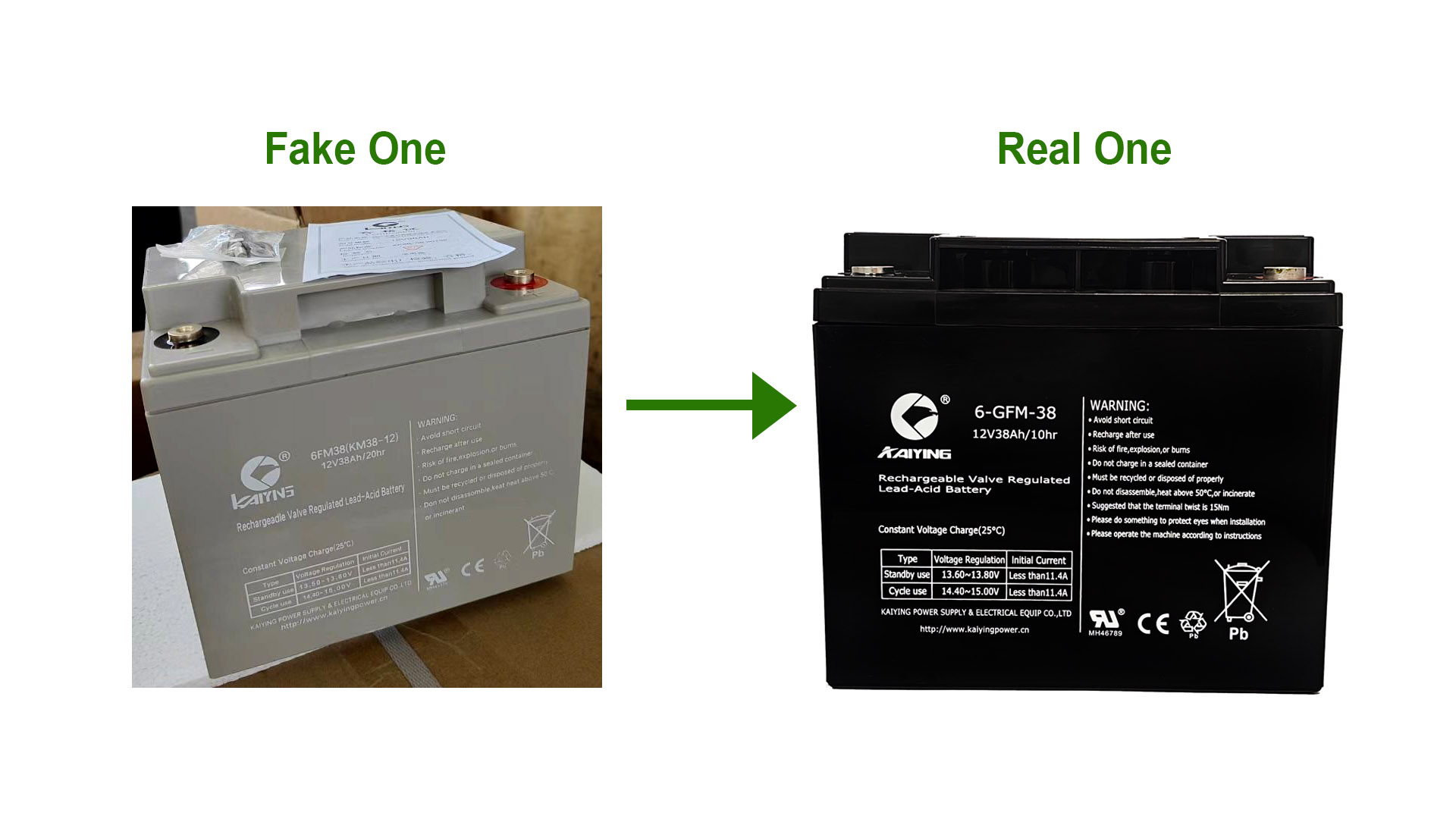

Poor Casing Quality: Counterfeit batteries have thin casings with numerous scratches.

Poor Casing Quality: Counterfeit batteries have thin casings with numerous scratches. Inferior Silk-Screen Printing: The silk-screen printing on counterfeit batteries contains errors in text, data, and certification codes, and is often blurry. These issues not only affect the product's appearance but also indicate unstable internal quality.

Inferior Silk-Screen Printing: The silk-screen printing on counterfeit batteries contains errors in text, data, and certification codes, and is often blurry. These issues not only affect the product's appearance but also indicate unstable internal quality.

Strict Quality Control: Fully automated production lines ensure consistency in every battery.

Strict Quality Control: Fully automated production lines ensure consistency in every battery. Quick Response: Support for model customization and bulk delivery.

Quick Response: Support for model customization and bulk delivery.